Critical Spaces, Hidden Risks

Why every facility needs proactive environmental monitoring

How do you choose the right materials if the wrong ones all promise to be perfect?

Facility managers and building owners today are navigating a construction landscape shaped by increasingly stringent codes, sustainability goals, budget limits and tenant expectations. Plumbing systems — while often hidden from view — play a foundational role in building performance, safety and longevity.

One of the key decisions every project faces is what kind of piping material to use for drain, waste and vent (DWV) systems. Traditional cast iron soil pipe has been around for generations.

Meanwhile, plastic options like PVC and ABS have gained traction for their perceived affordability and ease of use.

So which one is better?

The short answer: it depends. The longer — and more useful — answer comes from taking a closer look at how these materials perform across a range of real-world considerations. From sustainability and fire safety to acoustics and cost, this article explores how to make an informed, practical decision based on the long-term needs of your building.

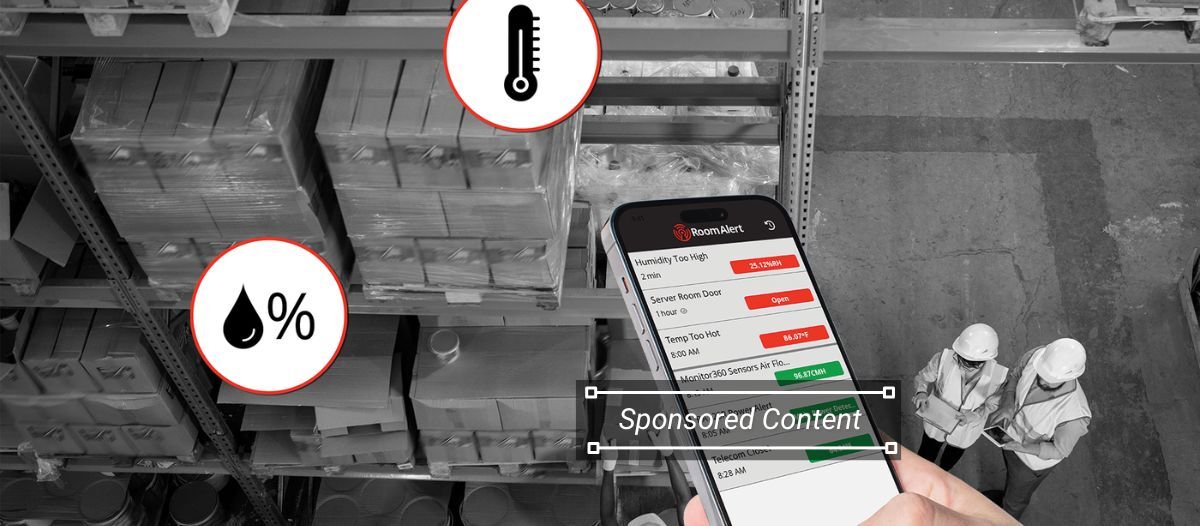

The expanding scope of environmental risk

The expanding scope of environmental risk

Today's facilities are more complex. Integrated smart technologies, sensitive electronics and growing regulations mean small environmental deviations can trigger cascading failures. Minor fluctuations quickly escalate into facility-wide crises, affecting operations, safety and compliance.

The hidden costs of environmental failures

Environmental monitoring failures create cascading effects that extend far beyond immediate equipment damage. When a server room overheats, the costs include not just hardware replacement but also data recovery, unexpected system outages and lost productivity. For healthcare facilities, temperature fluctuations in pharmaceutical storage can render entire inventories worthless, creating both financial losses and potential patient safety risks.

Research facilities face similar challenges with temperature-sensitive materials and equipment. A single environmental deviation can compromise months of research, destroy valuable specimens or invalidate critical test results.

Beyond direct financial impacts, environmental failures create safety and compliance risks that can have long-lasting consequences. Excessive humidity promotes mold growth, threatening indoor air quality and occupant health while potentially triggering costly remediation efforts. Temperature extremes can create hazardous working conditions that violate occupational safety requirements.

Regulated industries face additional penalties when environmental deviations violate storage requirements for pharmaceuticals, food products or research materials. These regulatory violations can result in fines, shutdown orders and damaged reputations that persist long after the initial environmental problem has been resolved.

Common facility blind spots

Server rooms & IT infrastructure

Server rooms and IT closets represent the most critical monitoring gaps in modern facilities. These spaces often house expensive equipment worth hundreds of thousands of dollars, yet many facilities rely solely on building-level HVAC monitoring rather than tracking actual conditions within these critical areas. IT equipment generates significant heat loads that can create localized hot spots even when building systems appear to function normally.

IT environments demand more than simple temperature monitoring. Modern data centers and server rooms require precise control of humidity, heat index and dew point. Equipment failures in these spaces don't just affect individual components, they can bring down entire networks which compromises business operations across the organization.

Server closets and telecom rooms often operate without environmental oversight, creating numerous failure points.

Storage & warehouse

Storage areas are another significant, often overlooked vulnerability. Housing documents, inventory or medical supplies, these spaces frequently lack monitoring despite their operational importance. Gradual humidity damage means problems often go undetected until extensive damage occurs.

Warehouse environments face unique challenges due to their size and varied storage requirements. Different areas within the same facility may require different environmental conditions, such as frozen storage, temperature-controlled pharmaceuticals and ambient inventory storage all within the same building. Traditional building management systems often cannot provide the granular monitoring needed to maintain appropriate conditions in each zone.

Cold storage facilities represent a specialized monitoring challenge where temperature deviations can result in massive product losses. Food service operations, pharmaceutical distribution and research facilities with cold storage requirements need monitoring systems that can detect problems before they compromise stored materials.

Manufacturing

Manufacturing facilities present complex environmental monitoring requirements that extend beyond comfort and basic equipment protection. Production processes often require precise environmental conditions to maintain product quality, worker safety and regulatory compliance. Temperature and humidity variations can affect product quality, equipment performance and worker productivity.

Mechanical & utility spaces

Mechanical and utility rooms, despite housing critical building infrastructure, commonly operate without environmental monitoring. These spaces can experience extreme temperature fluctuations that signal equipment problems or create conditions that accelerate component wear and failure.

HVAC equipment rooms, electrical distribution areas and utility spaces benefit from monitoring that can provide early warning of equipment problems before they impact building operations. Environmental conditions in these areas often serve as leading indicators of developing problems that could affect the entire facility.

Specialized facility areas

Healthcare facilities present unique monitoring requirements that extend beyond traditional comfort and equipment protection. Laboratory areas, imaging suites, surgical facilities and pharmaceutical storage all require precise environmental control to maintain patient safety and regulatory compliance.

Educational institutions face monitoring challenges in computer labs, research facilities, libraries with special collections and residence halls. Each of these environments presents different risk profiles and monitoring requirements that must be addressed to protect valuable assets and maintain operations.

Museums and cultural institutions require specialized monitoring to protect irreplaceable collections from environmental damage. These facilities often house materials that are extremely sensitive to temperature and humidity fluctuations, requiring sophisticated monitoring and control systems.

The evolution of building management systems

Building Management Systems (BMS) have revolutionized facility operations by providing centralized control of HVAC, lighting and security systems. However, while BMS technology has improved building efficiency and operational control, it often lacks the granularity and proactive capabilities needed to detect and address specific environmental changes in critical areas.

Traditional BMS platforms typically monitor environmental conditions at the zone or system level rather than in specific spaces where critical assets are located. This macro-level monitoring approach can miss localized environmental problems that pose significant risks to sensitive equipment or materials.

The integration gap between BMS and specialized environmental monitoring creates operational blind spots that can have serious consequences. While the BMS may indicate that HVAC systems are functioning normally, conditions in critical spaces may be deteriorating without detection.

Modern monitoring solutions & technology advances

Today's environmental monitoring technology has evolved far beyond simple thermostats or basic alarm systems. Modern technology can provide continuous proactive monitoring of multiple parameters including temperature, humidity, heat index, dew point, air flow, particulate matter, water/flood, power and more. These systems offer real-time visibility into facility conditions with sophisticated alerting capabilities that enable proactive response to developing problems.

Wireless advantages

Cable installation has long been the primary obstacle to comprehensive environmental monitoring, creating deployment challenges that left many critical areas unprotected. Wireless monitoring technology removes these barriers entirely, making it possible to monitor hard-to-reach locations, temporary spaces and areas where traditional wiring would be prohibitively expensive or disruptive to install.

Advanced sensor capabilities

Modern environmental sensors monitor multiple parameters simultaneously, providing comprehensive environmental visibility from single devices. Temperature, humidity, heat index and dew point monitoring from individual sensors reduces installation complexity while providing complete environmental data.

Sensor accuracy has improved dramatically, with high-precision devices now offering accuracy levels suitable for pharmaceutical, research and manufacturing applications that require strict environmental controls. This improved accuracy enables monitoring systems to detect smaller environmental deviations before they become critical problems.

Online monitoring platforms

Online monitoring platforms work in conjunction with installed environmental sensors and monitoring hardware to enable FMs to access real-time data from any location using smartphones, tablets or computers. These integrated systems collect data from sensors and transmit it to online monitoring platforms that provide 24/7 visibility into critical spaces with customizable alerting that can notify multiple personnel through various communication channels including mobile applications, text messages and email.

Advanced platforms analyze data collected from the physical monitoring equipment to provide historical data analysis capabilities that enable FMs to identify trends, optimize system performance and demonstrate compliance with environmental requirements. This data analysis capability supports predictive maintenance strategies and helps optimize facility operations.

The combination of installed hardware and remote monitoring accessibility ensures that FMs can respond to environmental problems regardless of their location, enabling faster response times and reducing the risk of minor problems becoming major failures.

Implementation strategies for comprehensive coverage

Risk assessment

Successful environmental monitoring begins with comprehensive risk assessment that identifies spaces housing critical assets, supporting essential operations or presenting environmental risks. FMs should prioritize areas with the highest risk potential while considering the cost of monitoring versus the potential cost of environmental failures.

Asset valuation should include not just replacement costs but also operational impact, regulatory compliance requirements and business continuity considerations. A server room containing $100,000 in equipment may support operations worth millions of dollars, making the monitoring investment calculation extend far beyond equipment replacement costs.

Risk assessment should also consider the probability of environmental problems in different areas. Spaces with aging HVAC equipment, inadequate ventilation or exposure to external environmental factors may require more intensive monitoring than areas with newer systems and better environmental controls.

Phased implementation approach

Implementation should be phased to provide immediate value in the highest-priority areas while allowing for system expansion as needs evolve and budgets permit. Starting with critical spaces such as server rooms or valuable storage areas can demonstrate technology value and build organizational support for broader deployment.

Phase one deployments typically focus on spaces with the highest risk and most significant potential impact. These initial installations provide immediate protection for critical assets while demonstrating the value of comprehensive environmental monitoring.

Subsequent phases can expand monitoring to additional areas based on lessons learned from initial deployments. This phased approach allows organizations to refine their monitoring strategies and optimize system configurations before investing in facility-wide coverage.

Sensor placement & coverage optimization

Sensor placement requires careful consideration of environmental dynamics, equipment layouts and potential risk sources. Simply installing one sensor per room may not provide adequate coverage in larger spaces or those with complex environmental patterns.

Professional assessment can optimize sensor placement for maximum monitoring effectiveness while minimizing system costs. Factors such as air circulation patterns, heat sources and potential failure points should all influence sensor placement decisions.

Alert configuration & response procedures

Alert thresholds should provide early warning of developing problems. Many facilities benefit from tiered alerting systems that provide different notification levels based on the severity and duration of environmental deviations.

Pre-alert notifications can warn FMs of environmental trends that may lead to problems, enabling proactive intervention before conditions reach critical levels. These early warning capabilities are particularly valuable for preventing equipment damage and maintaining optimal operating conditions.

Escalation procedures should ensure that appropriate personnel are contacted when environmental problems develop, with backup notification procedures for situations where primary contacts are unavailable. After-hours and weekend coverage requires particular attention to ensure environmental problems are addressed promptly regardless of when they occur.

Cost-benefit analysis & ROI considerations

Environmental monitoring investments should be evaluated based on comprehensive cost-benefit analysis that includes direct costs, potential savings and risk mitigation value. The cost of monitoring systems is typically minimal compared to the potential costs of environmental failures.

Insurance considerations may include premium reductions for facilities with comprehensive monitoring systems, as well as improved claims outcomes when environmental incidents do occur. Some insurance providers offer favorable rates for facilities demonstrating proactive risk management through environmental monitoring.

Energy efficiency benefits from environmental monitoring can provide ongoing operational savings that help offset system costs. Monitoring data can identify opportunities for HVAC optimization and energy conservation that reduce operating expenses.

Moving forward

Environmental monitoring represents a fundamental shift toward proactive facility management, enabling organizations to prevent problems rather than react to them after damage occurs. In an era of increasing facility complexity, growing regulatory requirements and rising operational costs, comprehensive environmental monitoring has become essential for protecting facility assets, maintaining operational continuity and ensuring organizational resilience.

For more information on how to protect your facility with proactive environment monitoring, visit AVTECH.com/facilities-protection!

Read more on

Explore All FMJ Topics