From Maintenance to Momentum

Annual planning strategies for facility leaders

Every fall, planning season returns. Across industries, facility and operations leaders dive into spreadsheets, forecasts, and strategy sessions — turning performance data into next year’s roadmap. The goal is simple: build a plan that keeps buildings running, assets healthy and budgets under control.

Every fall, planning season returns. Across industries, facility and operations leaders dive into spreadsheets, forecasts, and strategy sessions — turning performance data into next year’s roadmap. The goal is simple: build a plan that keeps buildings running, assets healthy and budgets under control.

But the path to get there is anything but simple.

Facility management sits at the intersection of cost, comfort and continuity. Whether you manage a single corporate campus or a global real estate portfolio, your maintenance plan has to balance competing priorities — uptime versus budget, sustainability versus speed, data precision versus human bandwidth. And all of it happens against a backdrop of shrinking labor pools, rising capital costs and constant technological change.

For many IFMA members, the annual maintenance plan goes far beyond scheduling tasks. It’s a practical roadmap that ties everyday operations to the organization’s bigger goals.

Why annual planning matters more than ever

When the economy tightens or leadership changes, maintenance spending is often one of the first areas questioned. But data from thousands of Limble CMMS users tells a consistent story: teams with an annual maintenance plan spend less over time. They see 15-30 percent lower downtime, fewer emergency repairs, and better asset longevity — all because they set intentional goals and track the right metrics.

An annual plan does three things especially well:

1. Connects maintenance to business priorities: It translates reliability, safety, and comfort into measurable business outcomes — lower operating costs, improved uptime, higher tenant satisfaction and reduced risk exposure.

2. Creates focus and accountability. Defined goals and measurable milestones give you a clear view of progress, making it easy to see what’s working and where to adjust.

3. Builds credibility with leadership. Numbers speak the language of executives. When maintenance data connects directly to business KPIs, it positions your team as a strategic partner — not a cost center.

As The Annual Maintenance Plan Handbook puts it, “Maintenance is critical for business continuity. The key to leveraging it is a well-crafted annual maintenance plan.”

The unique challenge for IFMA members

Facility management brings a level of unpredictability that manufacturing rarely faces. While a production line runs a steady cycle, a facility portfolio must adapt to shifting weather, changing occupancy, volatile energy costs and the constant evolution of tenant expectations.

That means IFMA professionals deal with a wider, more unpredictable set of maintenance drivers:

-

Asset diversity: From HVAC systems and elevators to life-safety systems and landscaping, every asset class follows its own maintenance logic.

-

Multiple stakeholders: Facility managers must satisfy occupants, finance teams, sustainability officers, and corporate leadership — often with conflicting priorities.

-

Aging infrastructure: Many commercial and institutional buildings are decades old. Deferred maintenance has compounded, and modernization efforts compete for limited funds.

-

Data fragmentation: Work orders may live in spreadsheets, vendor portals, or legacy CMMS tools that don’t talk to each other.

-

Workforce constraints: Skilled trades professionals are retiring faster than replacements enter the field. Knowledge transfer has become a planning risk.

In short: while manufacturing leaders may fight unplanned downtime, facility managers fight unplanned everything.

Building the plan: A framework for facility professionals

Every strong plan starts with alignment — not just among technicians, but across departments. IFMA members routinely tell us that the hardest part of maintenance planning isn’t the technical work; it’s the translation work. Turning facility realities into business language that finance and executives understand.

The following framework, drawn from Limble’s Annual Maintenance Plan, adapts that process for the facility management environment.

Align with the organization’s goals first

The strongest maintenance plans begin with business strategy. Understand how leadership defines success, then build your objectives to support it.

-

When cost containment is the priority, target initiatives that extend asset life and lower utility spend.

-

When the focus is on growth or new construction, prioritize scalability, capital planning, and facility readiness.

-

When sustainability is the priority, link maintenance actions directly to carbon-reduction metrics or ESG reporting.

When maintenance goals mirror corporate objectives, leadership sees the connection — and budgets start to follow.

Tip: If you’re not part of the executive planning discussions, create your own seat. Bring data on downtime, cost per square foot, or deferred maintenance trends to demonstrate how your team impacts larger business outcomes.

Translate pain points into measurable goals

Every facility team has recurring headaches — aging HVAC systems, inconsistent contractor performance escalating repair spend. Write each as a “pain point,” then flip it into a goal.

|

Pain Point |

Company Goal |

Maintenance Focus |

|

Escalating energy bills |

Reduce energy consumption |

Optimize HVAC and BAS schedules |

|

Frequent comfort |

Improve occupant |

Increase PM compliance for |

|

Deferred maintenance |

Reduce corrective work by |

Prioritize top 20 percent of |

This simple table turns frustration into action. It’s how one manufacturing facility in our handbook identified downtime and inventory cost as twin priorities — and cut both within a year.

Choose metrics that matter

Facility managers don’t need 50 KPIs — they need five that matter. Common enterprise-level metrics include:

-

Uptime percentage (availability): The proportion of time critical systems are operational.

-

Maintenance cost per square foot: A direct link to budgeting and benchmarking.

-

Preventive maintenance compliance: Percentage of PMs completed on time.

-

Mean time to repair (MTTR): Efficiency of the response process.

-

Work order aging: Visibility into backlog management.

In a CMMS, these metrics can be automated and visualized for weekly or monthly reporting. As the handbook puts it, “Measure a lot, report on a few.” The goal isn’t more data; it’s better decisions.

Build a realistic timeline

Once priorities are set, map them to the calendar. Most IFMA professionals juggle dozens of initiatives — retrofits, seasonal maintenance, capital projects, audits and compliance tasks.

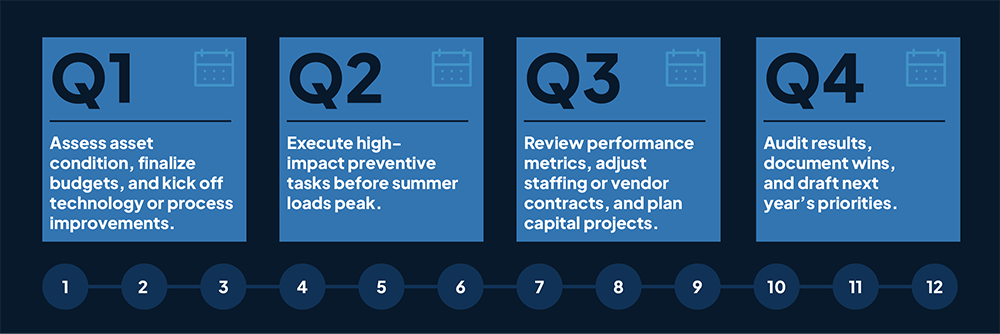

Organize them quarterly:

-

Q1: Assess asset condition, finalize budgets and kick off technology or process improvements.

-

Q2: Execute high-impact preventive tasks before summer loads peak.

-

Q3: Review performance metrics, adjust staffing or vendor contracts, and plan capital projects.

-

Q4: Audit results, document wins, and draft next year’s priorities.

By linking maintenance activity to seasonal facility cycles, you keep the plan both grounded and flexible — a key skill in facilities management, where reactive needs never fully disappear.

Align the right people & technology

In a world of hybrid work and dispersed portfolios, technology alignment is as critical as asset alignment. A modern CMMS is the foundation, but integration with energy management, building automation, and procurement systems is what unlocks real efficiency.

For IFMA members managing enterprise portfolios, the question isn’t whether to digitize — it’s how to do it without disrupting operations.

A few guiding principles:

-

Choose simplicity over flash. A CMMS your technicians actually use is worth more than one packed with unused AI modules.

-

Prioritize interoperability. Look for systems that connect with your ERP, accounting, or BAS tools.

-

Empower mobility. Field techs need mobile access for work orders, asset data, and documentation.

-

Secure buy-in early. Involve technicians and supervisors in pilot testing; their feedback drives adoption.

Technology doesn’t fix maintenance problems — it amplifies good processes and exposes bad ones.

Don’t forget the people behind the plan

Even the best strategy fails without engagement. Facility managers often sit between corporate policy and hands-on technicians, translating expectations in both directions. Effective annual planning doesn’t stop at process and performance — it also invests in people.

Three areas deserve focus:

-

Training and development. Equip your team with current knowledge on systems, safety, and compliance. A well-trained technician can prevent the kinds of issues that never make it into a report.

-

Recognition. Make success visible. Whether through dashboards, town halls, or internal newsletters, showcase progress in uptime, efficiency and cost control. Recognition reinforces accountability and pride in the work.

-

Knowledge capture: As senior staff retire, document tribal knowledge into digital job plans and PM checklists.

Highlighted in our Annual Maintenance Planning Guide, formalizing PM checklists not only improves consistency but also cuts average PM time by 20 percent. For IFMA members managing multiple buildings, that level of efficiency scales fast.

Planning across a portfolio

IFMA’s enterprise members face an added complexity — distributed assets and decentralized data. When facilities span states or continents, “standardization” can sound idealistic. But the payoff of consistent planning is enormous.

Here’s what enterprise-level planning looks like in practice:

-

Unified goals: Each facility develops its own annual maintenance plan aligned to the same corporate priorities.

-

Centralized metrics: Uptime, cost per square foot, and PM compliance are tracked consistently across sites.

-

Shared templates and processes: Whether through a CMMS or corporate facilities portal, standardized forms keep everyone on the same page.

-

Quarterly reviews: Data from each site rolls up into a corporate dashboard, making it easy to spot high-performing facilities and those that need support.

This approach transforms facility management from a cost center into a data-driven business function. Leadership sees not just maintenance spend, but maintenance ROI.

The human & strategic ROI

It’s easy to view planning as paperwork, but for many IFMA members, it’s a retention strategy. A structured maintenance plan means fewer emergencies, better work-life balance and a culture that values foresight over firefighting.

When teams shift from 90 percent reactive to 90 percent planned, morale rises along with reliability. Technicians feel trusted and empowered. Leaders get cleaner data and more predictable budgets. And the organization gains resilience — a key differentiator when supply chains or energy markets fluctuate.

Making the case to leadership

Even with the best plan, approval isn’t automatic. Executives want proof. Here’s how to earn it:

-

Lead with outcomes. Instead of saying “We need $250,000 for HVAC upgrades,” say “We’ll reduce energy consumption 12 percent and improve tenant comfort scores by 15 points.”

-

Use data storytelling. Pair dashboards with a simple narrative: “Here’s the problem, here’s the goal, here’s the metric.”

-

Show incremental wins. If you cut unplanned work by 10 percent in the first quarter, share it. Progress builds confidence.

-

Frame maintenance as risk management. Tie actions to safety, compliance, and business continuity — priorities every executive understands.

When maintenance speaks the language of outcomes, leadership listens.

Planning for 2026: What’s changing

Facility leaders planning for 2026 will face a different landscape than they did even three years ago. Three trends are reshaping how IFMA members approach maintenance strategy:

-

Sustainability mandates are tightening. Energy performance standards and ESG reporting are now board-level priorities. Maintenance plans must show measurable environmental impact.

-

AI and automation are becoming mainstream. Predictive tools, smart sensors, and digital twins are no longer experimental—they’re scalable. The challenge is integrating them responsibly.

-

The workforce shift continues. As generational turnover accelerates, institutional knowledge must be captured digitally, and recruitment strategies need to highlight purpose, not just pay.

The good news? Facility professionals are uniquely positioned to lead these transformations. Maintenance data is the connective tissue between sustainability, technology, and people — and the annual plan is how you weave it together.

Wrapping up: The plan is the proof

Every facility leader knows that the real test of a plan isn’t how it looks on paper — it’s how it performs when the lights flicker, the chiller fails or the CFO calls.

That’s why annual maintenance planning isn’t about predicting every problem. It’s about creating a system resilient enough to handle whatever comes next.

When done right, it elevates maintenance from a line item to a leadership function — one that protects assets, empowers people, and drives measurable business outcomes.

So, as you build your 2026 maintenance plan, remember:

-

Start with goals, not tasks.

-

Measure a few things that matter.

-

Align people, technology and process.

-

Review, report and refine.

Because in facility management, planning isn’t just preparation — it’s performance.

This article draws on insights from Limble’s Annual Maintenance Planning Guide and the field experience of thousands of maintenance leaders worldwide. For a complete planning guide and templates, visit limblecmms.com/resources.

Read more on

Explore All FMJ Topics