Optimizing Natural Gas in Facilities

Using analytics for safety & energy efficiency

Facility audits are essential for ensuring the safe and efficient management of critical infrastructure. With rising energy demand, aging facilities and volatile natural gas prices driven by geopolitical factors, facility managers face the significant challenge of detecting and preventing natural gas leaks. These leaks pose safety risks, incur high operational costs and negatively impact the environment. Real-time data from smart meters offers a transformative solution by enabling a shift from periodic, manual inspections to continuous, data-driven monitoring.

FMs can use globally applicable methodologies, best practices and actionable strategies for conducting effective facility audits, with a focus on natural gas systems while incorporating lessons for electric and water utilities.

The rationale for comprehensive facility audits

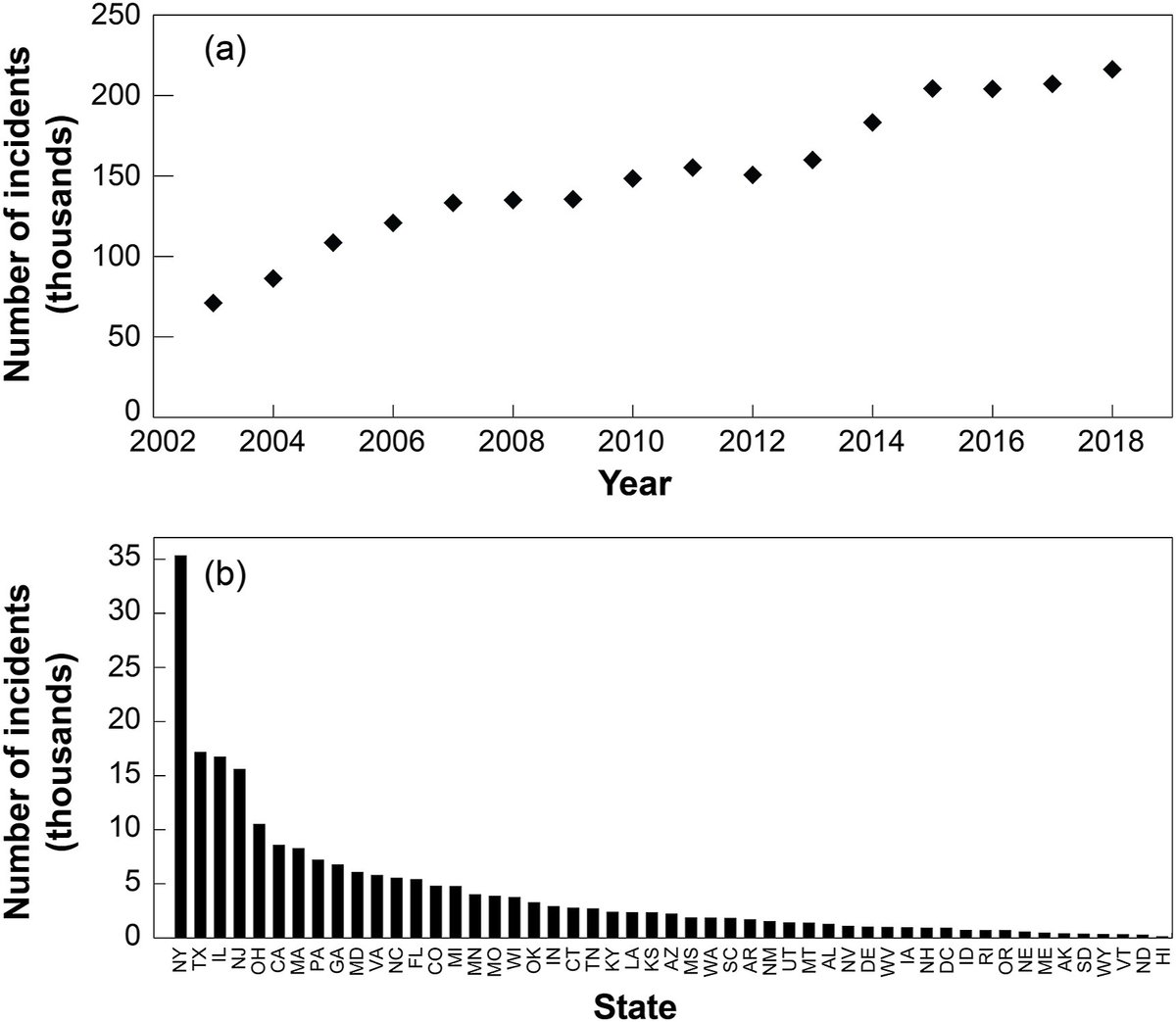

Globally, FMs contend with outdated monitoring systems, inefficient energy use and the hidden dangers of undetected utility leaks. In natural gas systems alone, nearly 630,000 leaks occur annually — with roughly 200,000 requiring emergency responses and about 300 gas explosions are recorded each year. The economic burden is immense; for example, in the U.S. alone, fire departments may spend more than US$500 million annually on gas-related incidents.

Environmental consequences are equally severe. Methane, the primary component of natural gas, has a global warming potential 84 times that of carbon dioxide over 20 years. Moreover, fluctuating natural gas prices amplify the importance of efficiency, as changes in cost directly affect operational budgets. Capturing real-time data enables early detection of leaks and inefficiencies, allowing for targeted interventions that prevent disasters, lower costs and contribute to global climate goals.

Key components of an effective facility audit

1. Safety assessments:

Facility audits must identify hazards such as undetected natural gas leaks, malfunctioning appliances and structural vulnerabilities. Continuous data streams from smart meters offer real-time insights that alert managers to abnormal consumption patterns, enabling rapid interventions before hazards escalate.

2. Energy efficiency evaluations:

Comparing historical utility consumption with real-time data allows FMs to identify inefficiencies. Benchmarking against industry standards helps pinpoint areas for maintenance or upgrades, yielding significant energy savings. This is particularly important given that while electric and water systems often have high advanced metering infrastructure (AMI) penetration, only about 40 percent of natural gas systems currently do.

3. Operational & maintenance reviews:

A thorough review of maintenance schedules and operational protocols is crucial. Automated data collection combined with regular physical inspections allows FMs to detect deviations early and schedule preventive maintenance, minimizing downtime and unplanned repairs.

4. Regulatory compliance & data portability:

Emerging global standards and data-sharing regulations, such as those underpinning the European Union’s General Data Protection Regulation (GDPR), drive the modernization of utility data systems. Although designed primarily to benefit consumers, these standards also encourage the adoption of advanced monitoring systems that facilitate effective facility audits.

5. Cost-benefit analysis:

Quantifying potential savings from improved energy efficiency and reduced emergency responses is essential. By comparing the costs of unchecked gas leaks — such as emergency dispatches, repairs and downtime — with the benefits of proactive monitoring, facility managers can make informed decisions about investments in modern technology.

Methodology for conducting a facility audit

A systematic approach is essential for a successful facility audit:

1. Pre-audit preparation:

Gather historical utility bills, maintenance records and incident reports. Develop a checklist tailored to the facility’s utility systems and coordinate with utility providers to access real-time data via platforms similar to Green Button or UtilityAPI.

2. Data collection:

Employ both automated sensor data and manual inspections. For natural gas systems, continuous readings from smart meters are vital. Depending on the technology deployed, data intervals may vary from near real time (one-minute updates) to hourly snapshots, providing the detailed information needed to identify anomalies.

3. Data analysis & benchmarking:

Analyze the collected data using statistical tools and visualize it against industry benchmarks. Abnormal usage patterns, such as prolonged gas consumption by an appliance, may indicate a leak or inefficiency that warrants further investigation.

4. On-site inspection:

Complement data analysis with physical inspections of critical infrastructure — gas lines, appliance connections and safety systems — to verify digital findings and ensure that issues are genuinely problematic.

5. Reporting & recommendations:

Compile findings into a detailed report that summarizes identified risks, inefficiencies and compliance gaps. This report should provide actionable recommendations and include a cost-benefit analysis to support decisions regarding further investments, such as drafting a request for proposal (RFP) for external services if needed.

Leveraging real-time data for proactive management

Transitioning from periodic audits to continuous, real-time monitoring represents a significant advancement in FM. Real-time data collection enables immediate detection of issues — if a gas meter registers unexpected usage on an appliance like a stove, an alert is triggered instantly. This proactive monitoring prevents prolonged hazardous conditions and reduces the likelihood of emergencies. Additionally, correlating consumption data with external factors such as weather conditions allows FMs to optimize energy use and respond swiftly to deviations, enhancing both safety and efficiency.

Impact of Live Natural Gas Usage Data During Extreme Weather Events

Copper Labs influenced demand response for natural gas during an extreme weather event.

Copper Labs influenced demand response for natural gas during an extreme weather event.

Case comparisons: Traditional audits versus real-time monitoring

Traditional facility audits, which rely on manual inspections and periodic reviews of downloaded utility data, often result in delays that allow issues to persist. In contrast, real-time monitoring systems provide continuous oversight, leading to early detection of anomalies. For example, if an appliance is accidentally left on for an extended period, traditional methods might not reveal the problem until hours later, while real-time systems can alert managers immediately. This proactive approach not only enhances safety but also reduces energy waste and minimizes emergency response costs.

Environmental & health impacts of advanced monitoring

The environmental benefits of real-time utility monitoring extend far beyond immediate cost savings. By implementing data-driven monitoring, facility managers can significantly reduce these emissions, supporting global efforts to lower greenhouse gas outputs and improve public health.

Cost & efficiency considerations

Key cost drivers for FMs addressing natural gas leaks include emergency response expenses, unplanned maintenance downtime and infrastructure repair costs. Traditional methods often involve high labor costs and delayed responses, which exacerbate these issues. Real-time monitoring solutions, on the other hand, continuously capture and analyze gas consumption data, allowing for immediate alerts and quicker interventions. Metrics such as gas consumption (measured in cubic feet), frequency and duration of abnormal usage events, and response times should be tracked to calculate the return on investment (ROI). Over time, the cost savings from reduced emergency responses and improved energy efficiency can significantly offset initial investments, particularly in the context of fluctuating natural gas prices.

Natural Gas Price Volatility Affects Overall Cost Efficiency

Natural gas prices often fluctuate during extreme weather and geopolitical factors.

Regulatory & compliance considerations

Global trends in data sharing and utility data portability are increasingly driving the adoption of advanced monitoring systems. Regulations mandating that utility data be provided in a structured, machine-readable format — such as those embodied in the European Union’s GDPR — are prompting utilities to modernize their data systems. Although FMs may not need to directly engage with these regulations, the broader movement toward transparency and data accessibility supports the implementation of real-time monitoring systems. This compliance ensures that facility audits are both effective and aligned with international best practices.

Preparing effective RFPs for facility audits

When contracting external services for advanced facility audits, a comprehensive request for proposal (RFP) is critical. An effective RFP should include:

-

A clear project overview: A concise summary of identified risks and inefficiencies.

-

Specific objectives & desired outcomes: Expected improvements in emergency response times, energy efficiency and cost savings, supported by data-driven projections.

-

A detailed scope of work: Requirements for data integration, performance metrics and project timelines.

-

Evaluation criteria: Objective criteria for vendor selection, emphasizing technical expertise, cost-effectiveness and alignment with global standards. An objective, data-focused RFP ensures that facility managers secure proposals that precisely address their needs while meeting international standards.

Future outlook & trends in FM

Digital transformation is reshaping facility management worldwide. Innovations in artificial intelligence (AI), the Internet of Things (IoT) and blockchain are continuously enhancing real-time monitoring capabilities, enabling FMs to derive actionable insights from vast amounts of data. Trends such as enhanced customer experiences, real-time decision-making and continuous system optimization are driving the evolution of facility audits. As utilities expand smart meter networks and integrate comprehensive data pipelines, the potential for predictive, data-driven energy audits will increase, offering significant operational and environmental benefits.

Actionable insights for FMs

Facility managers are encouraged to adopt several data-driven strategies to optimize operations:

-

Leverage real-time data: Integrate live data from smart meters to continuously monitor utility usage, enabling the early detection of anomalies and swift corrective actions.

-

Establish regular audits: Implement a routine schedule for facility audits that incorporate real-time monitoring to prevent costly emergencies and maintain compliance with safety and environmental standards.

-

Engage with data providers: Utilize freely available resources and standardized data platforms, such as those offered by the Green Button Alliance, to access comprehensive utility data.

-

Prepare data-driven RFPs: Base RFPs on accurate, real-time data to clearly define facility challenges and desired outcomes, ensuring objective, globally applicable proposals.

-

Track key metrics: Monitor gas consumption rates, incident frequency and response times to measure efficiency improvements and justify investments in advanced monitoring technologies.

Additional Resources

For further guidance on advanced facility audits, the following ungated resources are recommended:

- The U.S. Department of Energy’s “Guide to Energy Audits” provides detailed methodologies and case studies demonstrating the benefits of proactive energy management. (energy.gov/eere/buildings/articles/guide-energy-audits)

- The Green Button Alliance offers insights into standardized utility data practices and is a valuable resource for integrating real-time data.

- Utility data platforms, such as those offered by UtilityAPI, provide accessible data to enhance facility audits and support data-driven decision-making.

Conclusion

Facility audits are a cornerstone of modern FM, offering the insights needed to enhance safety, reduce operational costs and support environmental sustainability. By leveraging real-time data from smart meters and integrating advanced technologies such as AI, IoT and blockchain, FMs can shift from reactive, periodic inspections to dynamic, continuous monitoring systems. These systems not only detect potential hazards before they escalate but also provide actionable data that drives preventive maintenance and operational efficiency. As the adoption of smart meters increases globally and natural gas prices continue to fluctuate, the evolution of facility audits will be crucial in shaping a safer, more efficient and environmentally sustainable future for organizations worldwide.

Read more on Technology , Risk Management and Sustainability or related topics Energy and Data strategy and information management

Explore All FMJ Topics